FA9200 model redesign beating stroke and shedding based on TSUDAKOMA ZAX9200 model. By employing the offset rocking shaft with less moment of inertia and a hollow reed holder,beating is well-balanced. In addition to stable operation at high speeds,faster than all conventional model,the FA9200 has ow vibration and saves electricity.

| item |

specifications |

spare parts |

| Reed Width |

Nominal Reed Space(CM) |

150,170,190,210,230,260,280,300,320,340,360 |

|

| Useful reed space(CM) |

Norminal R/S:0-60cm(150-250cm),0-80cm(>280cm) |

|

| Working Range |

|

Short yarn:me100-ne2.5 Filament:22dtex-1350dtex |

|

| Weft Selection |

|

1.2.4 or 6 color |

|

| Motor |

Start Mode |

Start motor at high speed |

|

| Push-button start,stop,f/r slow move |

|

| Push-button switch handed |

|

| Power |

2.8Kw,3.0Kw,3.8Kw,4.5Kw |

|

| Weft Insertion |

Method |

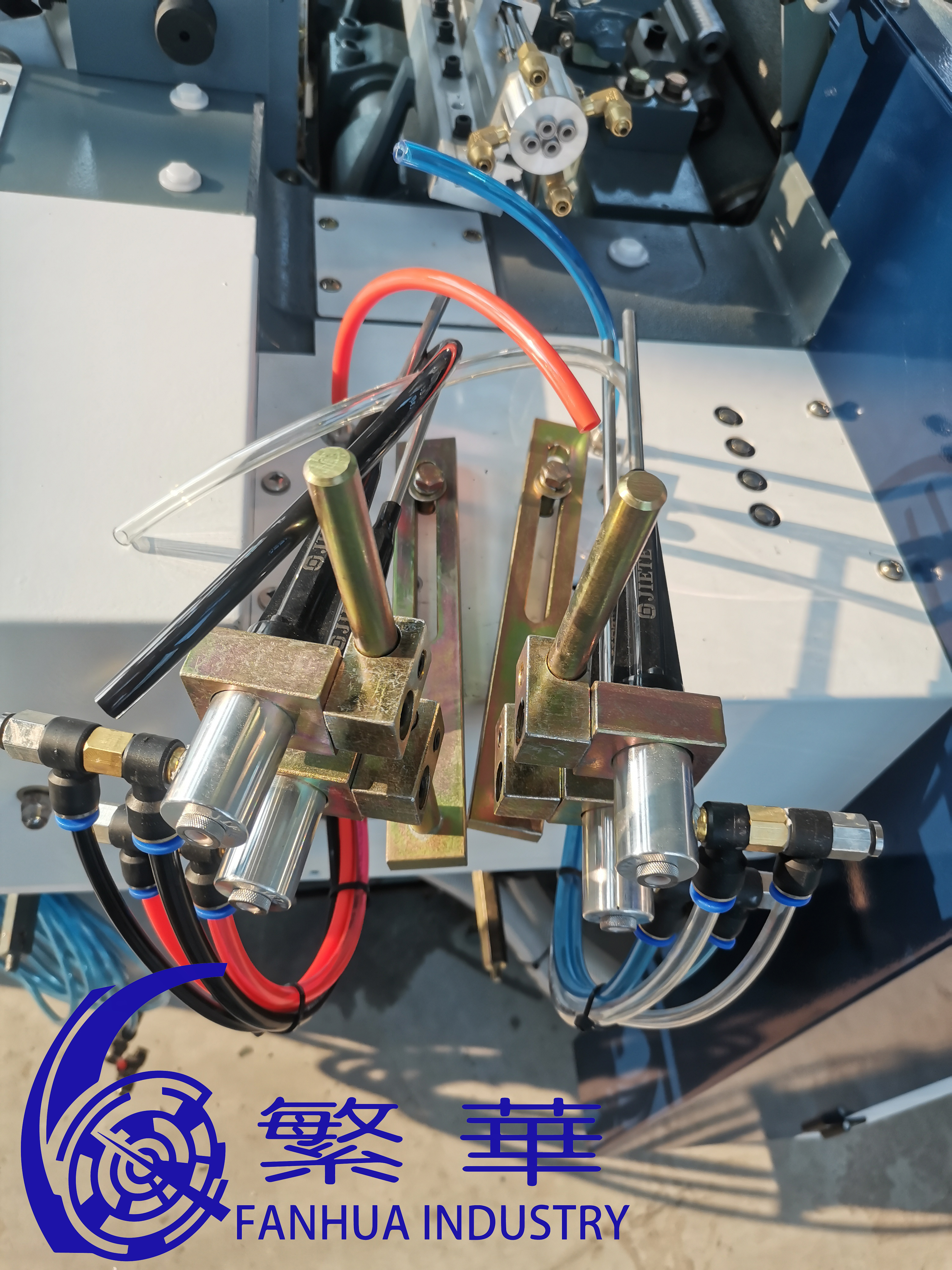

Main nozzle+swing nozzle+sub nozzle+abnormity lock |

Weft brake |

| Control |

Import High-frequency solenoid valve,computer program control |

|

| supporting spray solenoid vavle |

Supporting spray solenoid valve integrated with flow cavity |

|

| Measuring weft storage |

Electric control loop separate weft storage |

Ballooning Prevention Device |

| Beating |

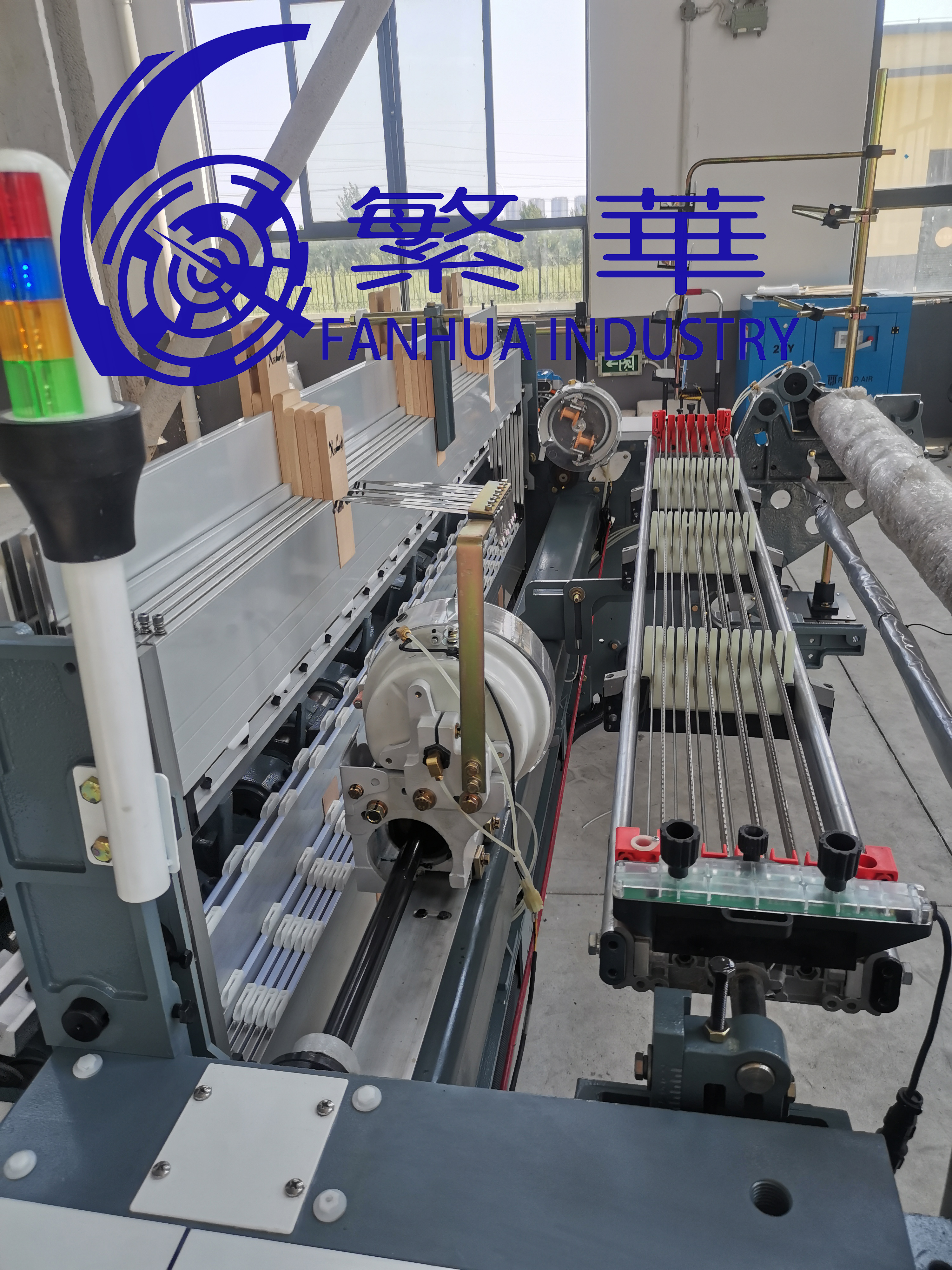

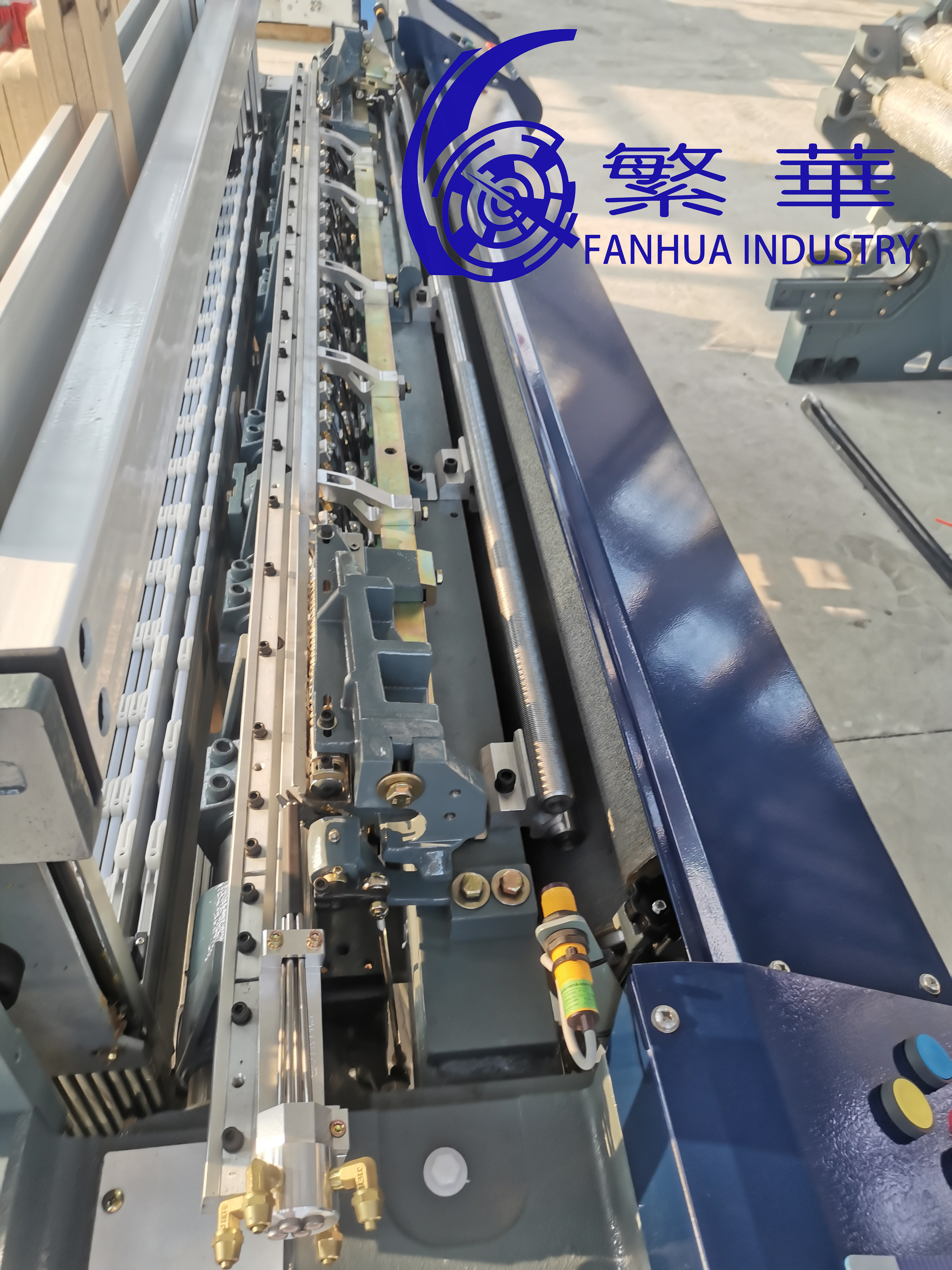

Beating-Up Motion |

Double side tank oil-bath type four-bar beating-up motion |

|

|

Multi-sleysword solid beating-up warp and weft system |

|

|

Multi supporting base,balance weight |

|

| Shedding |

|

Crank type flat sheddingg(heald frame 4 to 8);1/1 fabric |

|

| Down positive Cam shedding(heald frame 4 to 14);Plain,twill,satin,black out babric |

|

| Dobby shedding(heald frame 16 max);Plain,twill,satin or complex design |

|

| Electronic Jaquard shedding:1344,2688 lifting hooks |

|

| Let off |

|

Electric servo continuous let-off |

Double-warp beam |

| Twin back beam |

|

| Positive or negative let off |

|

| flang Dia |

Φ800mm |

Φ1000mm |

| Take up |

Batching Method |

Mechanical continuous take-up |

Electric servo continuous take-up |

| Batching Method |

Entrails batching(Max dia:1000mm) |

|

| Temple |

Lower or upper |

|

| Selvage |

|

Leno yarn by planetary gears |

|

| lubrication |

|

For main driving parts:oil-bath type,centralized filling oil(grease) |

|

| Shutdown device |

Weft breakage |

Reflecting double feeler device |

|

| Warp breakage |

Electric warp stop device |

|

| others |

Selvage,yarn end treatment,end-broken stop motion |

|

| Shutdown display |

Screen display,multi-functional shutdown display lights |

|

| Weft cutter |

|

Mechanical cutter |

|

| Electric control system |

|

High deficiency,large screen,vga color image display touch human-computer interface |

|

QINGDAO FANHUA INDUSTRY CO, LTD has progressively become the world’s leading manufacturer of textile weaving technologies, providing professional weaving looms-water jet loom, air jet loom,velvet looms, etc.

We serve the global market with exceptional machinery for high speed water jet looms, high speed air jet looms, velvet looms, etc. Products are mainly sold to India, Pakistan, Vietnam, Indonesia, Turkey, Uzbekistan, Brazil, and other countries. There are sales and after-sales service centers in India and Indonesia.

We have professional engineers, production team and after-sales service, and constantly update and upgrade our looms to create our own unique technical features.

1)Are you manufacturer:

Yes, we are manufacturer of water jet loom, air jet loom, rapier looms,twisting machine,etc. textile weaving looms. And at present we also increased the mask making machines series lines.

2)Do you attend the exhibition every year?

Yes, we attend the india, indonesia,Parkistan,shanghai china,Uzbekistan,Turkey etc.textile exhibition every year.

3) Do you have office in foreign market?

Yes,we have office in suzhou,china; in india, in indonesia, welcome to visit us.

4)What is the delivery time?

We can deliver the looms within one month 300 sets.

5)Do you already register in India government?

Yes, already become the member of ATUFS india.

6)Do you have aftersales team?

Yes, we will arrange the after sales teams on the door when delivered the looms on your side. Any problems of prompt time is within in 2 hours.