Supply OEM China Spark High Speed Air Jet Loom, with Staubli Dobby, 2 or 4 Color

“Sincerity, Innovation, Rigorousness, and Efficiency” will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for Supply OEM China Spark High Speed Air Jet Loom, with Staubli Dobby, 2 or 4 Color, We sincerely welcome domestic and foreign retailers who phone calls, letters asking, or to plants to barter, we’ll supply you excellent products and solutions plus the most enthusiastic provider,We look ahead on your check out as well as your cooperation.

“Sincerity, Innovation, Rigorousness, and Efficiency” will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for China Air Jet Loom, High Speed Weaving Machine, Customer satisfaction is our goal. We’ve been looking forward to cooperating with you and providing our best services to suit your needs. We warmly welcome you to contact us and you should feel free to contact us. Browse our online showroom to see what we can do for you personally. And then E-mail us your specifications or inquiries today.

* Video

* Description

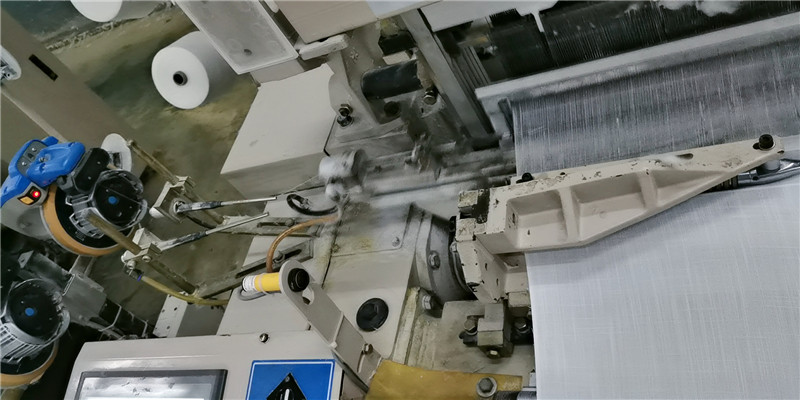

The shedding mechanism of WA9200 model is optional: crank shedding, cam shedding,electronic dobby and jacquard, with electronic let-off, electronic take-up, and weft changing dense weaving function; broken warp self stopping, double weft detection electronic measurement, electronic weft , stranded edge yarn detection and weft cating yarn inspection are all controlled by electronic control, so that the operation is more humanized.

The reasonable beam structure: to further optimize the beam structure, the change of warp tension sensing more sensitive. After the tension roller bracket installed on the outer side of the frame, which is convenient for installation and maintenance. This series of looms have the advantages of high rigid frame structure and so on. It is suitable for weaving high density and fine fabric. It also has the electronic control, which can effectively reduce the probability of weaving defects, such as stop gear, mechanical gear, broken warp, short weft and so on, and improve the weaving quality.

* Main Feature

| item | specifications | spare parts | |

| Reed Width | Nominal Reed Space(CM) | 150,170,190,210,230,260,280,300,320,340,360 | |

| Useful reed space(CM) | Norminal R/S:0-60cm(150-250cm),0-80cm(>280cm) | ||

| Working Range | Short yarn:me100-ne2.5 Filament:22dtex-1350dtex | ||

| Weft Selection | 1.2.4 or 6 color | ||

| Motor | Start Mode | Start motor at high speed | |

| Push-button start,stop,f/r slow move | |||

| Push-button switch handed | |||

| Power | 2.8Kw,3.0Kw,3.8Kw,4.5Kw | ||

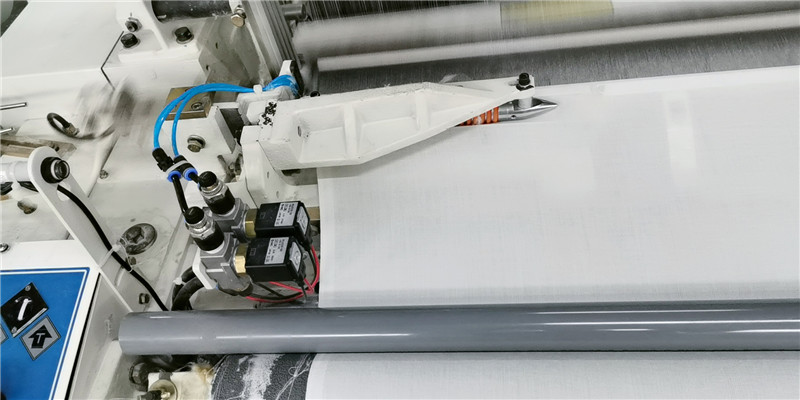

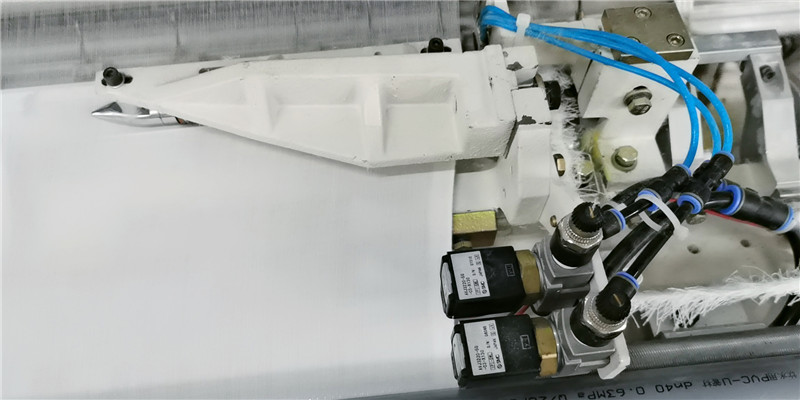

| Weft Insertion | Method | Main nozzle+swing nozzle+sub nozzle+abnormity lock | Weft brake |

| Control | Import High-frequency solenoid valve,computer program control | ||

| supporting spray solenoid vavle | Supporting spray solenoid valve integrated with flow cavity | ||

| Measuring weft storage | Electric control loop separate weft storage | Ballooning Prevention Device | |

| Beating | Beating-Up Motion | Double side tank oil-bath type four-bar beating-up motion | |

| Multi-sleysword solid beating-up warp and weft system | |||

| Multi supporting base,balance weight | |||

| Shedding | Crank type flat sheddingg(heald frame 4 to 8);1/1 fabric | ||

| Down positive Cam shedding(heald frame 4 to 14);Plain,twill,satin,black out babric | |||

| Dobby shedding(heald frame 16 max);Plain,twill,satin or complex design | |||

| Electronic Jaquard shedding:1344,2688 lifting hooks | |||

| Let off | Electric servo continuous let-off | Double-warp beam | |

| Twin back beam | |||

| Positive or negative let off | |||

| flang Dia | Φ800mm | Φ1000mm | |

| Take up | Batching Method | Mechanical continuous take-up | Electric servo continuous take-up |

| Batching Method | Entrails batching(Max dia:1000mm) | ||

| Temple | Lower or upper | ||

| Selvage | Leno yarn by planetary gears | ||

| lubrication | For main driving parts:oil-bath type,centralized filling oil(grease) | ||

| Shutdown device | Weft breakage | Reflecting double feeler device | |

| Warp breakage | Electric warp stop device | ||

| others | Selvage,yarn end treatment,end-broken stop motion | ||

| Shutdown display | Screen display,multi-functional shutdown display lights | ||

| Weft cutter | Mechanical cutter | ||

| Electric control system | High deficiency,large screen,vga color image display touch human-computer interface | ||

* Detail Picture

“Sincerity, Innovation, Rigorousness, and Efficiency” will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for Supply OEM China Spark High Speed Air Jet Loom, with Staubli Dobby, 2 or 4 Color, We sincerely welcome domestic and foreign retailers who phone calls, letters asking, or to plants to barter, we’ll supply you excellent products and solutions plus the most enthusiastic provider,We look ahead on your check out as well as your cooperation.

“Sincerity, Innovation, Rigorousness, and Efficiency” will be the persistent conception of our company to the long-term to establish together with customers for mutual reciprocity and mutual gain for Supply OEM China Spark High Speed Air Jet Loom, with Staubli Dobby, 2 or 4 Color, We sincerely welcome domestic and foreign retailers who phone calls, letters asking, or to plants to barter, we’ll supply you excellent products and solutions plus the most enthusiastic provider,We look ahead on your check out as well as your cooperation.

Supply OEM China Air Jet Loom, High Speed Weaving Machine, Customer satisfaction is our goal. We’ve been looking forward to cooperating with you and providing our best services to suit your needs. We warmly welcome you to contact us and you should feel free to contact us. Browse our online showroom to see what we can do for you personally. And then E-mail us your specifications or inquiries today.

www.wintoptexmachinery.com