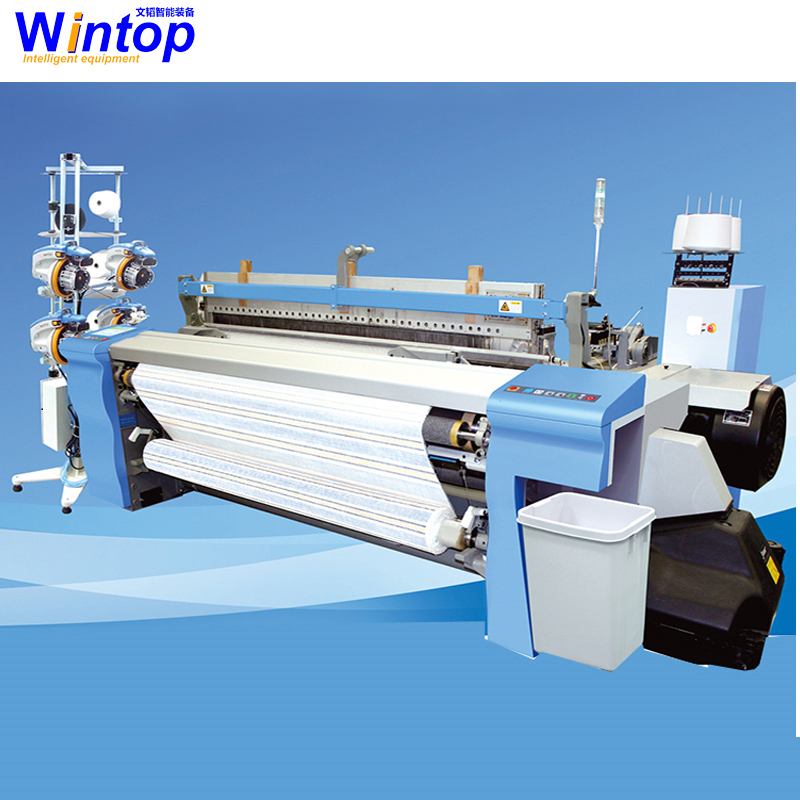

OEM Manufacturer Weaving Loom Machine - Bintian/Staubli Cam 8 Shafts Newlight Heald Frame High Speed Air Jet Loom WA9200 With Individual Inverter Leno Selvage Banner/IRO Feeder Electronic System|Cotton 100%Weaving Air Jet Machine – WINTOP

OEM Manufacturer Weaving Loom Machine - Bintian/Staubli Cam 8 Shafts Newlight Heald Frame High Speed Air Jet Loom WA9200 With Individual Inverter Leno Selvage Banner/IRO Feeder Electronic System|Cotton 100%Weaving Air Jet Machine – WINTOP Detail:

* Video

* Description

The shedding mechanism of WA9200 model is optional: crank shedding, cam shedding,electronic dobby and jacquard, with electronic let-off, electronic take-up, and weft changing dense weaving function; broken warp self stopping, double weft detection electronic measurement, electronic weft , stranded edge yarn detection and weft cating yarn inspection are all controlled by electronic control, so that the operation is more humanized.

The reasonable beam structure: to further optimize the beam structure, the change of warp tension sensing more sensitive. After the tension roller bracket installed on the outer side of the frame, which is convenient for installation and maintenance. This series of looms have the advantages of high rigid frame structure and so on. It is suitable for weaving high density and fine fabric. It also has the electronic control, which can effectively reduce the probability of weaving defects, such as stop gear, mechanical gear, broken warp, short weft and so on, and improve the weaving quality.

* Main Feature

| item | specifications | spare parts | |

| Reed Width | Nominal Reed Space(CM) | 150,170,190,210,230,260,280,300,320,340,360 | |

| Useful reed space(CM) | Norminal R/S:0-60cm(150-250cm),0-80cm(>280cm) | ||

| Working Range | Short yarn:me100-ne2.5 Filament:22dtex-1350dtex | ||

| Weft Selection | 1.2.4 or 6 color | ||

| Motor | Start Mode | Start motor at high speed | |

| Push-button start,stop,f/r slow move | |||

| Push-button switch handed | |||

| Power | 2.8Kw,3.0Kw,3.8Kw,4.5Kw | ||

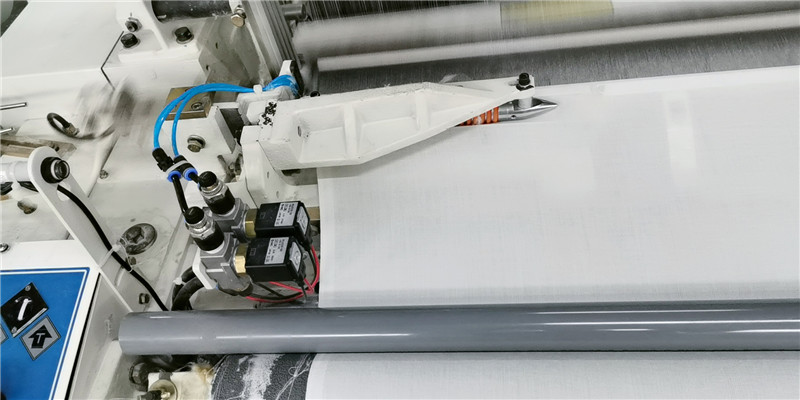

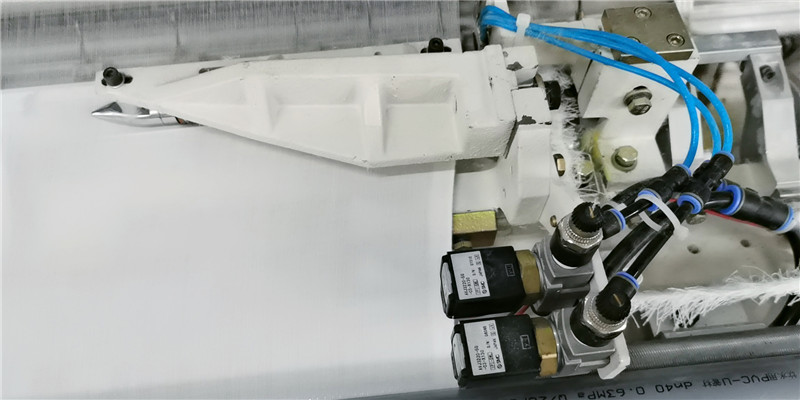

| Weft Insertion | Method | Main nozzle+swing nozzle+sub nozzle+abnormity lock | Weft brake |

| Control | Import High-frequency solenoid valve,computer program control | ||

| supporting spray solenoid vavle | Supporting spray solenoid valve integrated with flow cavity | ||

| Measuring weft storage | Electric control loop separate weft storage | Ballooning Prevention Device | |

| Beating | Beating-Up Motion | Double side tank oil-bath type four-bar beating-up motion | |

| Multi-sleysword solid beating-up warp and weft system | |||

| Multi supporting base,balance weight | |||

| Shedding | Crank type flat sheddingg(heald frame 4 to 8);1/1 fabric | ||

| Down positive Cam shedding(heald frame 4 to 14);Plain,twill,satin,black out babric | |||

| Dobby shedding(heald frame 16 max);Plain,twill,satin or complex design | |||

| Electronic Jaquard shedding:1344,2688 lifting hooks | |||

| Let off | Electric servo continuous let-off | Double-warp beam | |

| Twin back beam | |||

| Positive or negative let off | |||

| flang Dia | Φ800mm | Φ1000mm | |

| Take up | Batching Method | Mechanical continuous take-up | Electric servo continuous take-up |

| Batching Method | Entrails batching(Max dia:1000mm) | ||

| Temple | Lower or upper | ||

| Selvage | Leno yarn by planetary gears | ||

| lubrication | For main driving parts:oil-bath type,centralized filling oil(grease) | ||

| Shutdown device | Weft breakage | Reflecting double feeler device | |

| Warp breakage | Electric warp stop device | ||

| others | Selvage,yarn end treatment,end-broken stop motion | ||

| Shutdown display | Screen display,multi-functional shutdown display lights | ||

| Weft cutter | Mechanical cutter | ||

| Electric control system | High deficiency,large screen,vga color image display touch human-computer interface | ||

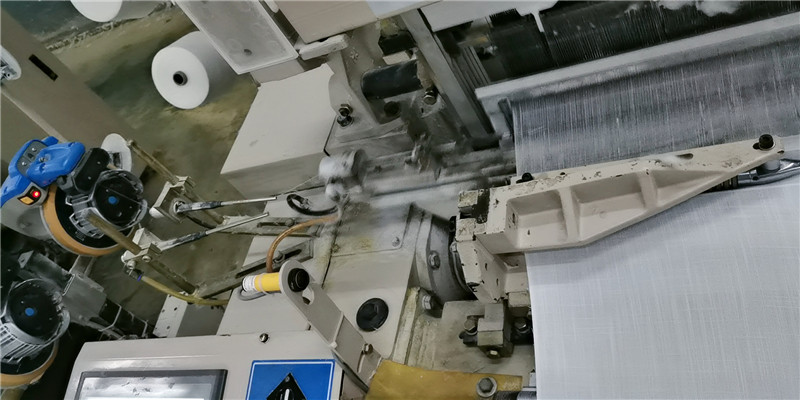

* Detail Picture

Product detail pictures:

Related Product Guide:

It is a good way to enhance our products and solutions and repair. Our mission will be to build creative solutions to consumers with a great experience for OEM Manufacturer Weaving Loom Machine - Bintian/Staubli Cam 8 Shafts Newlight Heald Frame High Speed Air Jet Loom WA9200 With Individual Inverter Leno Selvage Banner/IRO Feeder Electronic System|Cotton 100%Weaving Air Jet Machine – WINTOP, The product will supply to all over the world, such as: United Arab emirates, Niger, Greece, we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we've gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.