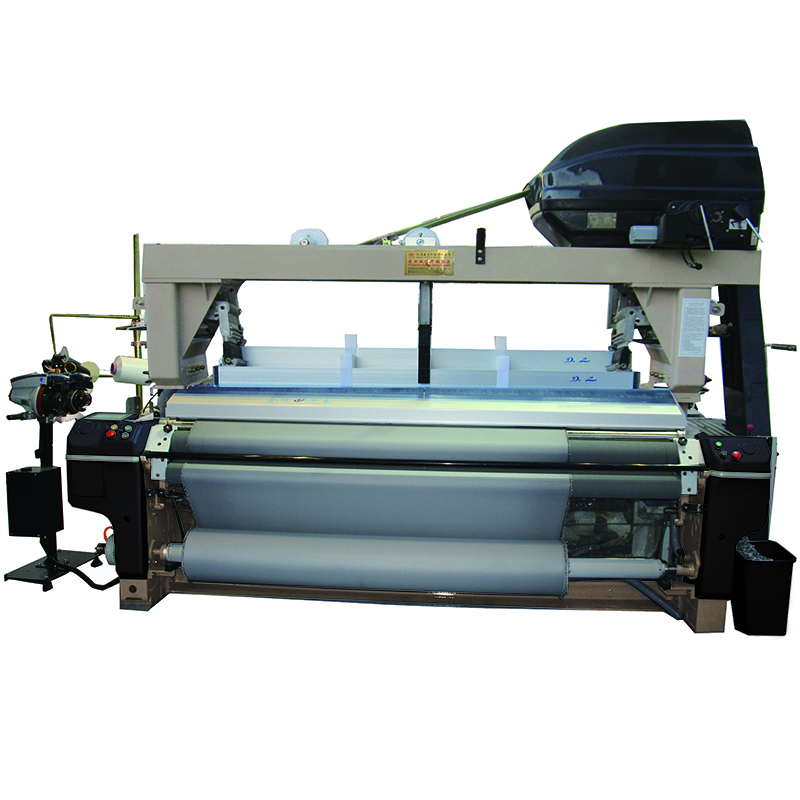

High Quality for water jet loom fabrics - High Speed Electricity Saving X motor Permanent Magnet Direct Drive System Water Jet Loom|Power Loom|Polyester Fabic Weaving Loom|TPM Weaving Water Jet Loom – WINTOP

High Quality for water jet loom fabrics - High Speed Electricity Saving X motor Permanent Magnet Direct Drive System Water Jet Loom|Power Loom|Polyester Fabic Weaving Loom|TPM Weaving Water Jet Loom – WINTOP Detail:

* Video

* Description

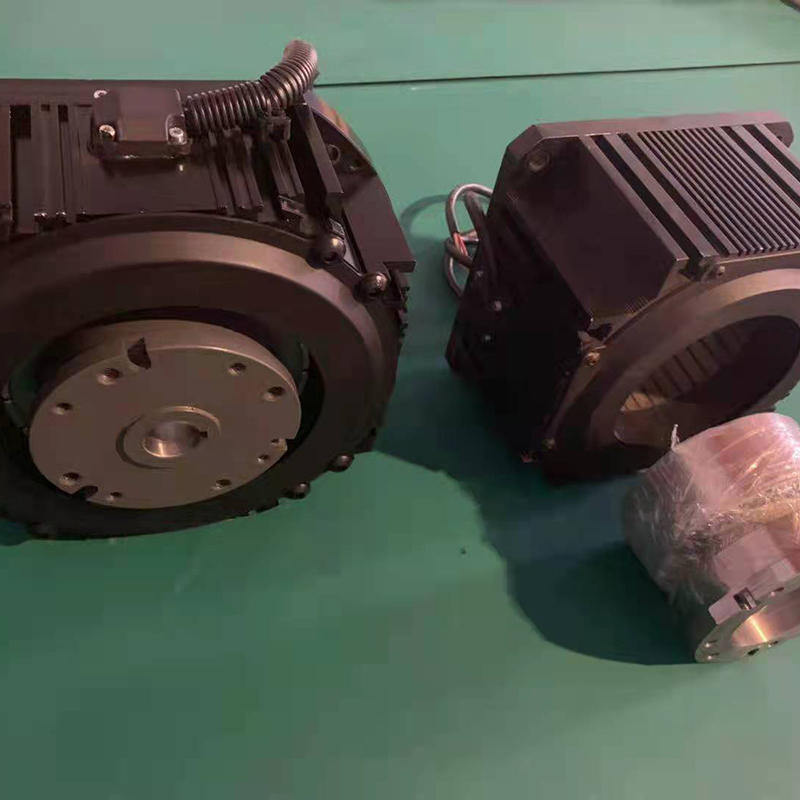

Energy-saving Mechanism

At present,the average efficiency of AC asynchronous motors in the industry is about 80%.The high efficiency range is about 75%-100% of the rated load.Meanwhile,the efficiency of the latest WINTOP ®products motor X enjoys a much higher efficiency than the standard performance of all the other types of original motors in the industry,which reaches an astonishing 93%.The high efficiency range is 25%-125%of the rated load.

Motor X has been desinged to be easily connected to the main axle.The mechanism components like beeak disc,pulley and the belt can be saved to lower the cost and reduce the kinetic energy loss owing to its direct drive axle structure.As a result,the energy saving rate of the whole scheme reaches to 15%-25%compared to the original type of looms.

Reliability

The SHT high temperature resistant magnet(up tp 150℃)was adopted in our motor X series in order to prevent the machine from the risk of degaussing.

The excellent sealing technology owned by us perfectly protect the weaving machine from the high humidity enviroment.

Energy Saving

The energy saving rate of the motor X is 15%-25%,which is equivalent to saving about $500usd per year and $48000 per 1000 water jet looms.It also makes it possible to have more equipment working at the same time under the same rated transformer.

Reducing Machinery Cost

Compared with the traditional AC asynchronous motor,the direct drive system saves the component cost of the motor,brake dics,belt and pulley,and has its own frequency conversion function,which is equivalent to and additionally saves the cost of installing frequency conversion.

Saving Labor Cost

The speed of the water jet looms can be changed freely to achive the efficient switching between different varieties and continuously improving the speed.Saving human cost.

Safety

Slow inching function can efficiency reduce the wear of the looms and protect he operators at the same time.

Improving Fabric Quality

To ensure the quality of the products,certain kinds of fabric may require a fixed angle to start-stop.Motor X series allows the loom to achieve this goal by meeting this technological requirements automatically.Even those workers who lack skills and experience can effectively control fabric quality.Reducing the rate of rags and production cost.

Increasing Output

The speed of the water jet looms can be changed freely to achieve the efficient switching between different varieties and continuously improving the speed.Increasing the output for weaving factory.

* Specification

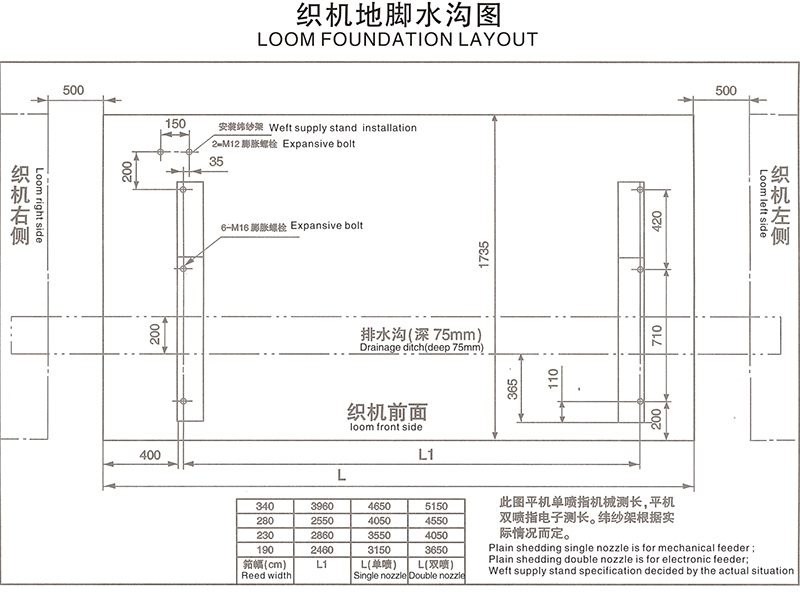

* Foundation Layout

Product detail pictures:

Related Product Guide:

"Based on domestic market and expand overseas business" is our development strategy for High Quality for water jet loom fabrics - High Speed Electricity Saving X motor Permanent Magnet Direct Drive System Water Jet Loom|Power Loom|Polyester Fabic Weaving Loom|TPM Weaving Water Jet Loom – WINTOP, The product will supply to all over the world, such as: Singapore, Dominica, Croatia, Our mission is "Provide Products with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.