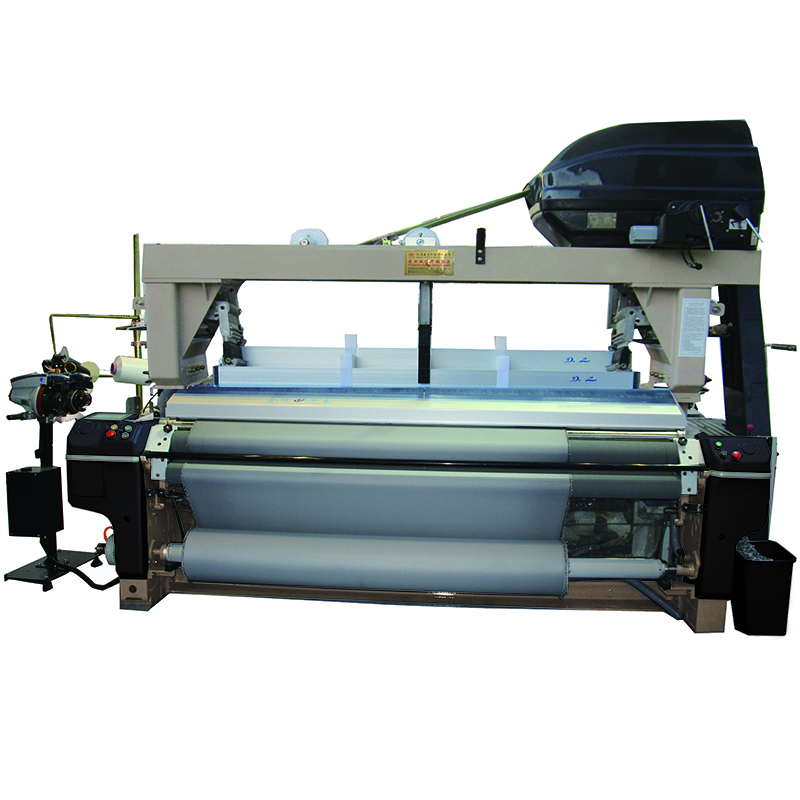

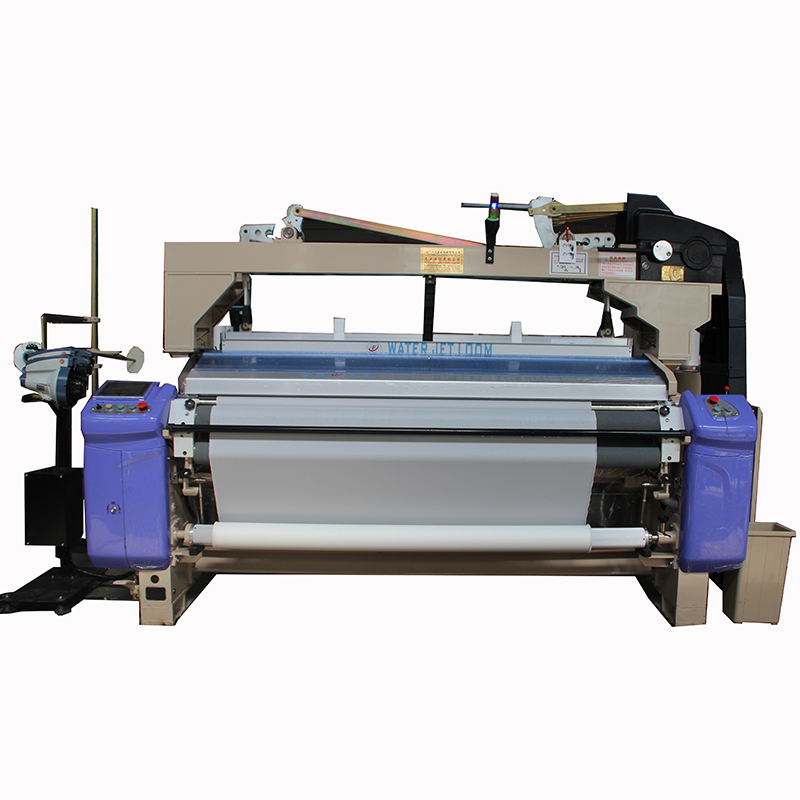

Cheap PriceList for Air Jet Loom With Reeling Frame Easy Design - High speed 150-450cm 1-8 colors mechanical or electric feeder plain crank shedding/cam shedding/dobby shedding/jacquard shedding with single pump or twin pumps high speed water jet loom WT406H at 1000RPM for TPM weaving – WINTOP

Cheap PriceList for Air Jet Loom With Reeling Frame Easy Design - High speed 150-450cm 1-8 colors mechanical or electric feeder plain crank shedding/cam shedding/dobby shedding/jacquard shedding with single pump or twin pumps high speed water jet loom WT406H at 1000RPM for TPM weaving – WINTOP Detail:

* Video

* Description

Low Vibration And High Efficiency

WT406H designed for the special fabric weaving like TPM with about 1000RPM,which is optimized the main component and frame structure improving the beating-up, the pentagon roller instead of L type, the ceramic rollers instead,let-off mechanism and take up mechanism,installing assistant device on let-off mechanism,all of this ensure the running stability and reduce vibration and noise,increasing efficiency and enlarging the waving range.

Weft Insertion

New “UH” type nozzle: a new nozzle with improved convergence of jetting water allows filling insertion with a small shedding open and saving water 15% comparing with normal nozzle the pitch between the nozzles is shortened.this decreases the difference between the filling inserting conditions of the two nozzles while filling insertion periods are the same. Consistent filling insertion under high speed operation is attained.

Soft Picking

Soft picking allows stable operation with loom even with less water jetting.the most important is that it will not damage the warp yarn during high speed operation.

Soft Filling Insertion At High Speed

The filling insertion angle is enlarged by improvements in beating curve,filling insertion for thick or twisted yarn is more stabilized. Further more,weaving is greatly improved on easily generates warp looseness during weaving.

New Material Cover

New color cover is used new material,which thickness is 3MM higher than former 851 and 408 model. And it is totally enclosed type.

* Detail

* Specification

| Type | WT406 | WT508 | WT8200 | |

| Reed Space(CM) | 135,150,170,190,210,230,260,280,300,320,340,350,360 | |||

| Useful reed space(CM) | Norminal R/S minus 2cm to 50cm | |||

| Frame | Box frame type Driving section is in oil bath | |||

| Driving | Brake | Direct stop mechanism by an electromagnetic brake | ||

| Controller | Push and touch button(Arrange,stop,forward,brake,reverse) | |||

| Motor | Rush start motor | |||

| Motor power | 1.5kw,1.8kw,2.2kw,2.7kw,3.2kw,3.7kw,4.5kw,5.4kw | |||

| Beating | Crank beating | |||

| Let off | system | Automatic mechanical and continuous let-off;Or electronic let-off,One or vertical two roll | ||

| warp beam | Φ800mm flange,Φ178mm barrel | |||

| Take up | system | Mechanical or electronic continuous take-up | ||

| Pick density | Normal:5-60picks/cm;Special:4-100picks/cm | |||

| Cloth wind-up diameter | Φ420mm,Φ520mm,Φ600mm | |||

| Shedding | Plain shedding | crank shedding(heald frame 2 to 8;1/1 fabric | ||

| Cam shedding | Cam shedding(heald frame 2 to 14);Plain,twill,satin babric | |||

| Dobby shedding | Positive/negative(heald frame 16 max.);Electronic and mechanical reading system;Plain,twill,sation or complex design | |||

| Jaquard | 1408,2688,5120 lifting hooks;electronic jacquard device | |||

| Weft insertion | Measuring and storage | 300#RDP type mechanical measuring turbo blower(single nozzle)Or electronic weft feeder(1-6nozzles) | ||

| Pump | M,L,H type, Single or Double | |||

| Plunger | Ceramic plunger;Φ32/Φ17,Φ32/Φ18,Φ32/Φ20,Φ36/Φ22,Φ36/Φ24,Φ36/Φ26,Φ39/Φ26,Φ39/Φ28,Φ39/Φ30,Φ50/Φ35 | |||

| Nozzle needle | ST20/10;ST30/10;ST45/20,SD75/40 | |||

| Weft filling | 1/2/3/4/6 nozzle | |||

| Filling feeder | Electronic,optical,and self-control | |||

| Selvage/Leno system | Twisting by star,planetary gears | |||

| Electrical part | Madeinchina/import | Main control board,AC contactor,transformer,NC interface,Selvagebrake system,Waste yarn brake system,overheating and overload protection | ||

| Electronic meter | count and display,rotational speed,total yield,team yield,total efficiency,team efficiency,cloth length auto control,stopping analysis and display | |||

| Other devices | take up roller-one;weft density gear-one;Trashcan-one;nozzle needle-one set | |||

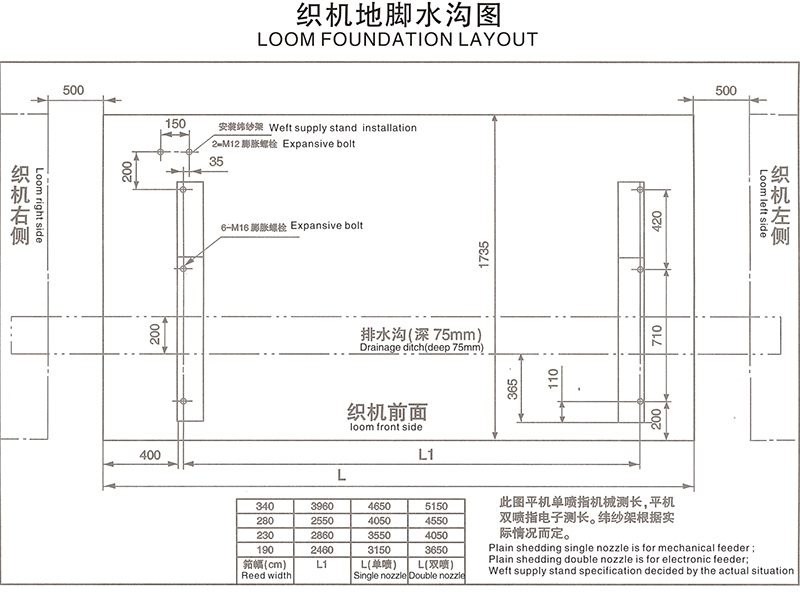

* Foundation Layout

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our organization for your long-term to establish alongside one another with shoppers for mutual reciprocity and mutual benefit for Cheap PriceList for Air Jet Loom With Reeling Frame Easy Design - High speed 150-450cm 1-8 colors mechanical or electric feeder plain crank shedding/cam shedding/dobby shedding/jacquard shedding with single pump or twin pumps high speed water jet loom WT406H at 1000RPM for TPM weaving – WINTOP, The product will supply to all over the world, such as: Bangladesh, Birmingham, Seattle, We've got constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. In depth Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!